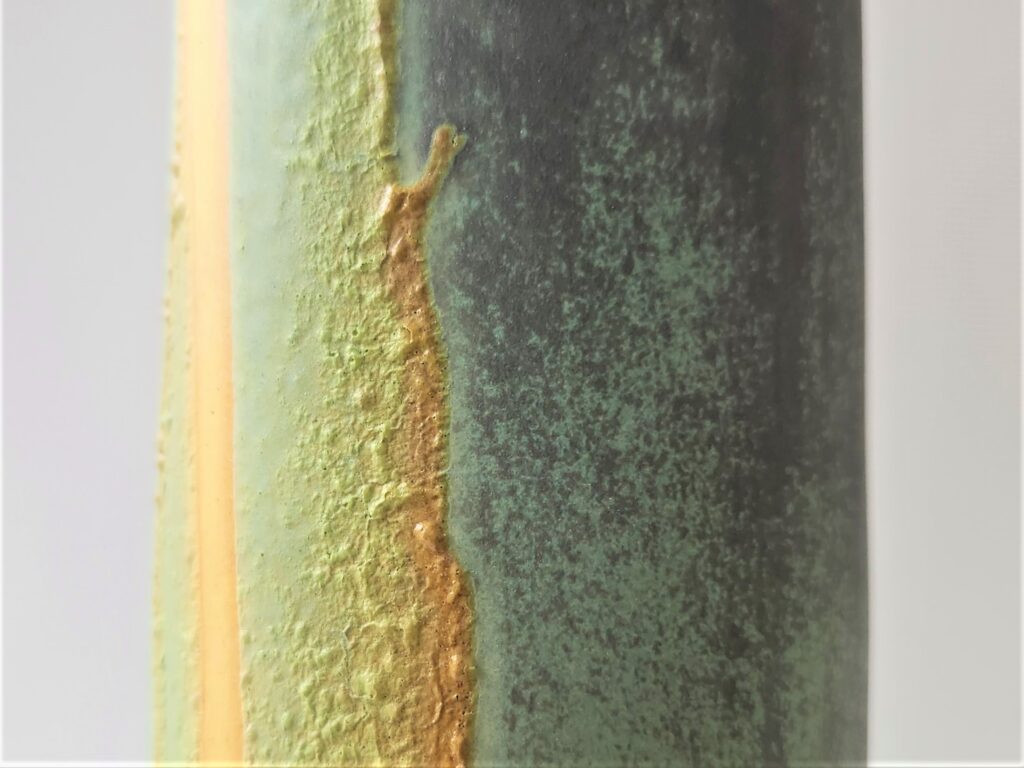

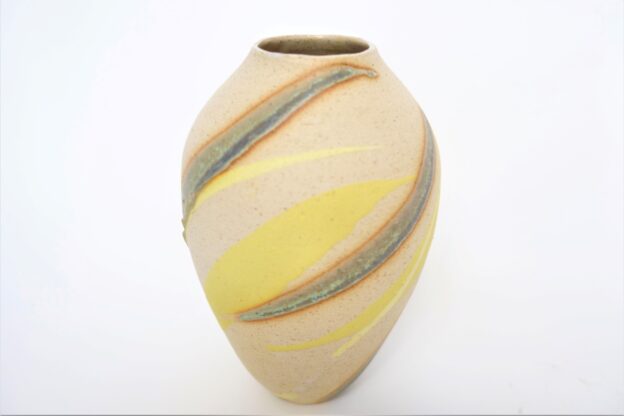

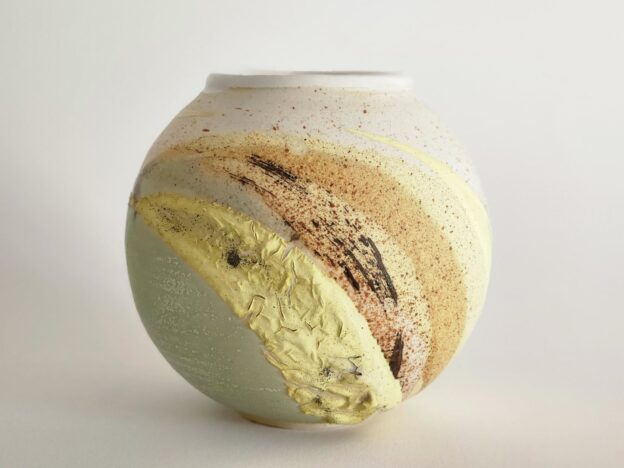

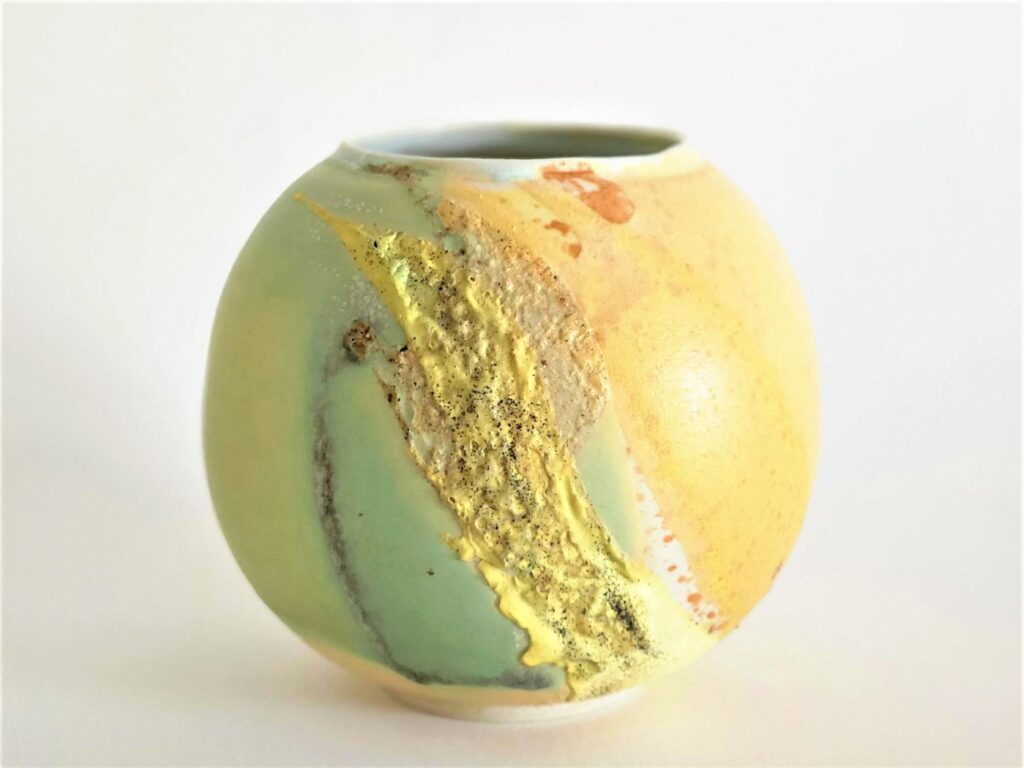

A pair of vases suggesting leaves, reeds and moss, all catching the light around the base of an age-old tree; a play on darkness, shadows and light.

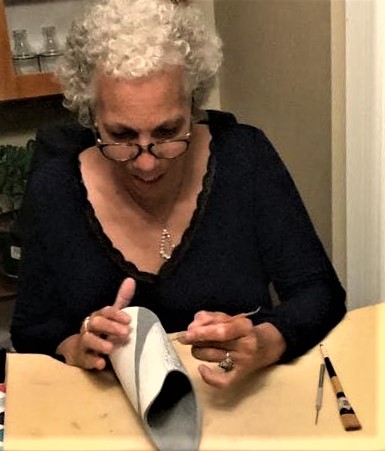

Hand built using a single slab of black stoneware clay, lightened with thinly-poured coatings of Frost porcelain. Yellow slip applied with a flick of the wrist, then sgrafitto<d to suggest waving leaves.

I submitted only one of these to the OGP 2023 Annual Exhibition, because the one on the right had a fault, and the submission deadline was up. A little sanding, a touch of slip, and into the kiln it went for a second cone 6 firing. All went well. From now on, this pair will stay together.

Height: 30 cm; Diameter at base: 8 cm.